PTC- Original Technologies and Trust

MAXMUM TECHNOLOGY

MAXMUM TECHNOLOGY

Internal resistance of lithium ion batteries increases on low temperature and so power reduces.

Therefore it is necessary to warm batteries on cold regions.

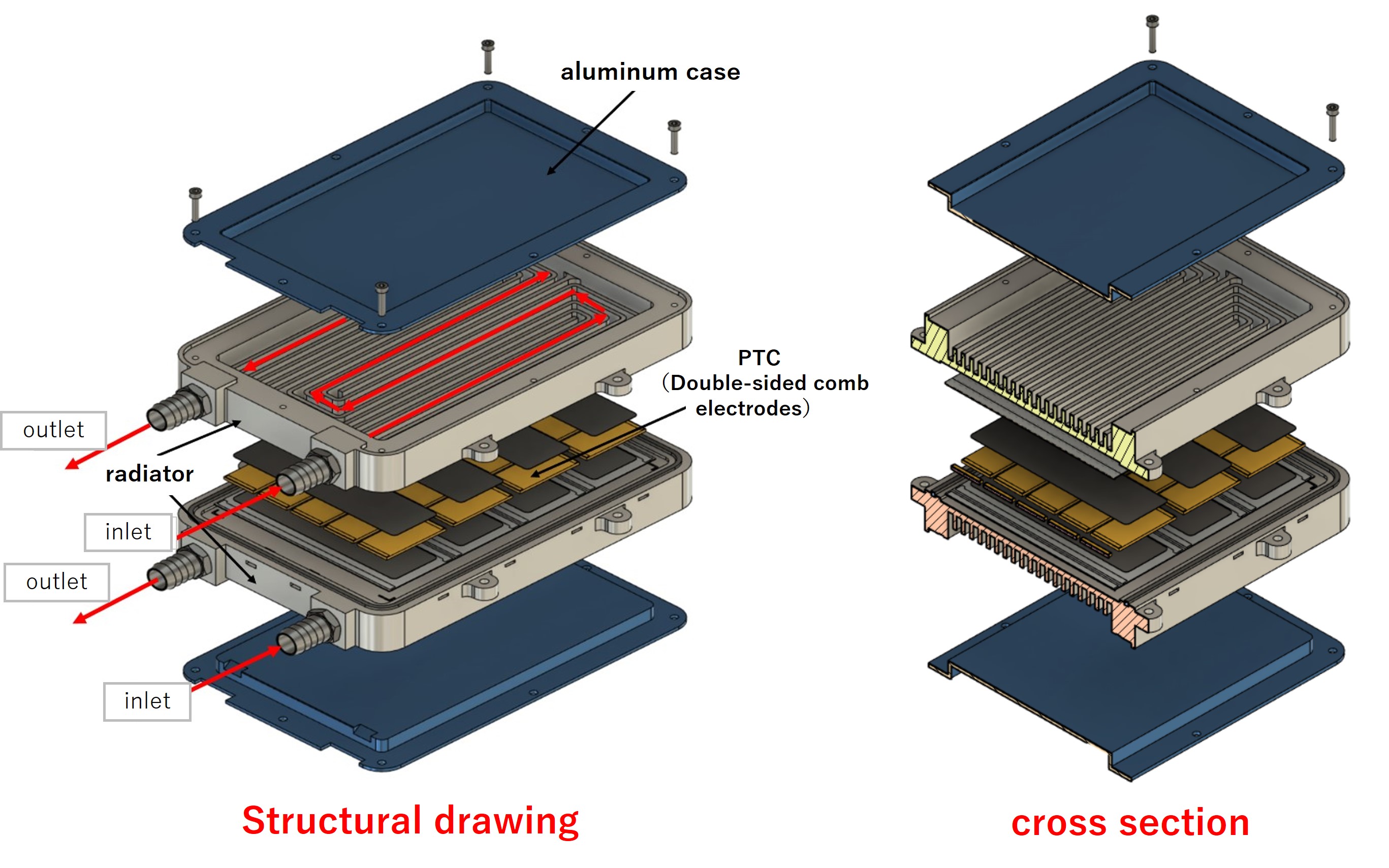

We developed high efficiency LLC heater with 2-stage flow path by sandwiching a PTC with unique comb electrodes between two heat sinks.

By circulating the heated LLC around the lithium ion battery, it can be fully charged even at low temperature.

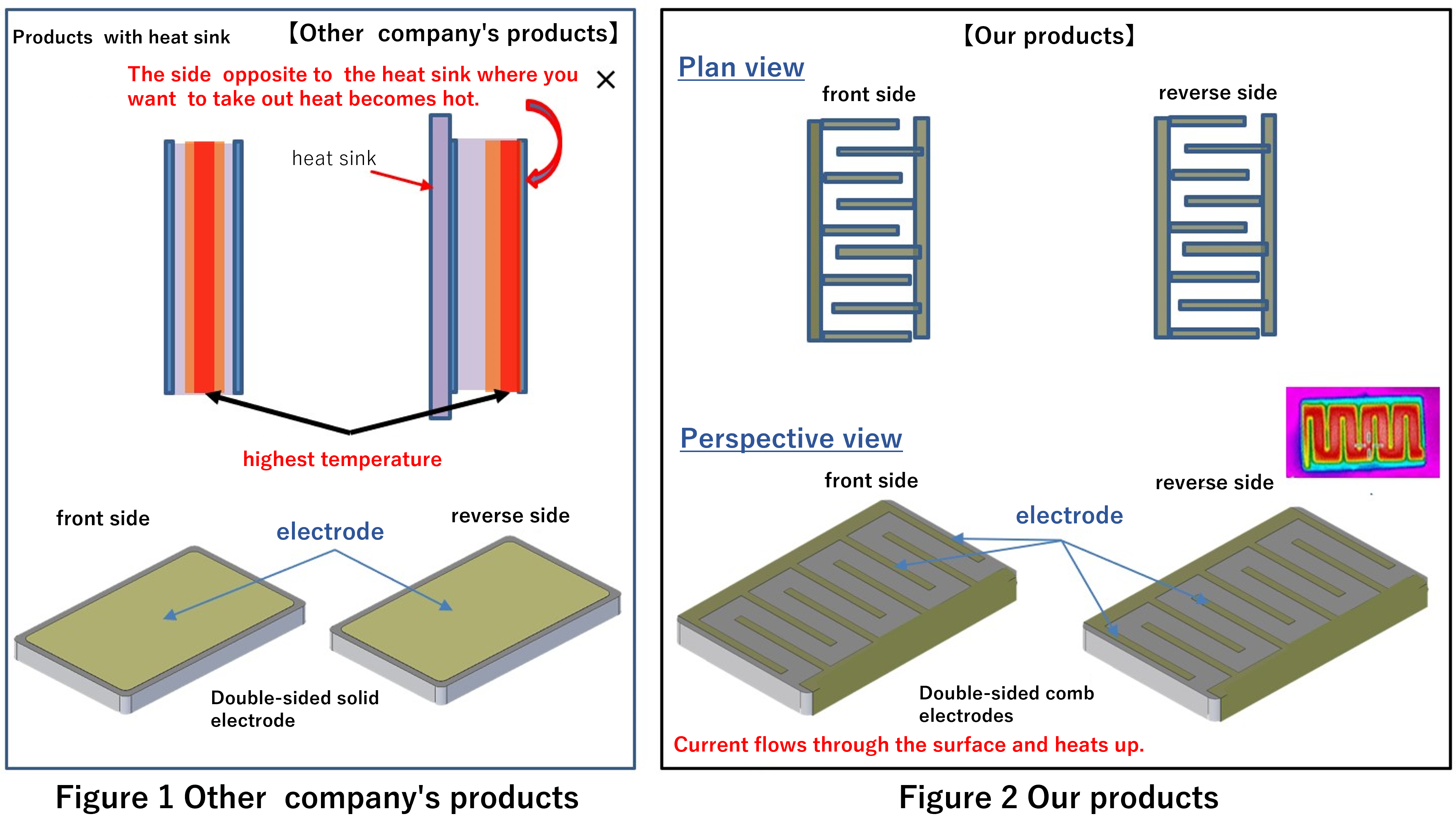

As shown in Fig.1, conventional PTC heaters have a structure in which electrodes are provided on both surfaces of the element and power is supplied from there.

As a result, heat point is generated inside of PTC, and surface temperature of PTC does not rise because the current do not flow.

Also, the side of the heat sink where we want to take out the heat does not get hot, and the opposite side gets hot, making it difficult to achieve high output.

Our PTC, which has comb-shaped electrodes on both surfaces of the element, has a heat-dissipating surface and a heat-generating surface that are the same as shown in Fig. 2, heat can be obtained efficiently

| Foreign automotive parts manufacturer | Japanese automotive parts manufacturer | MAXIMUM TECHNOLOGY | |

|---|---|---|---|

| Heating element | Nichrome wire | PTC/Double-sided solid electrode | PTC/Double-sided comb electrodes |

| Control device | required (high cost) | required (high cost) | Not required (low cost) |

| Fluid heating device | 1-stage | 1-stage | 2-stage |

| heating rate | slow | slow | fast |

| size | 370×280×130 | 350×260×100 | 260×220×60 |

| weight | 4.2kg | 3.8kg | 2.3kg |

| Reference price | ¥50,000 | ¥40,000 | ¥20,000 |